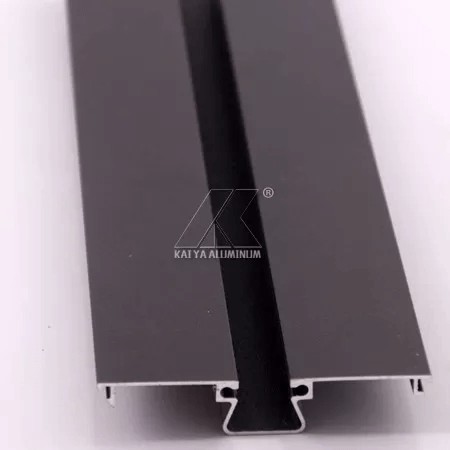

| ORIGIN OF PLACE: | Guangdong,China | ALLOY OR NOT: | Is Alloy |

|---|---|---|---|

| FINISH: | Powder Coating | LENGTH: | Customized |

| TEMPER: | T3-T8 | USAGE: | Windows |

| COLOR: | Black | ||

| HIGH LIGHT: | aluminum window profile aluminum window frame profile | ||

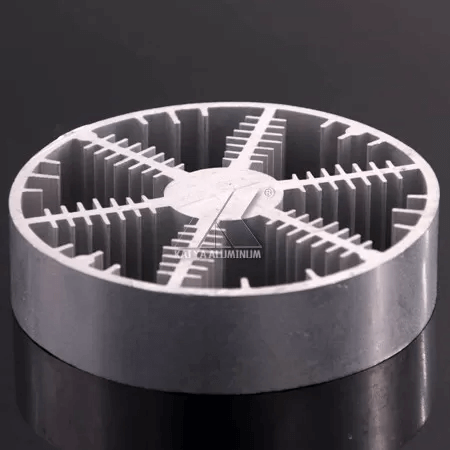

Black Powder coating High Grade Alloy Windows Style Aluminum Extrusted Profile

Prodictopm Description

| Brand Name | Kaiyamei Aluminum |

| Material | 6063 Alloy |

| Temper | T3 – T8 |

| Thickness | General profiles thickness:0.8 – 5.0 mm; |

| Color | Anodized protection thickness: 8 – 10μm Powder coating protection thickness: 40-80μm |

| Diameter | Customize |

| Length | 5.8-6.0m, or as cuostomer request |

| Color | 3D Wood Grain as your requests |

| Surface Treatment | Mill finish , anodize, powder coating , elecrophoresis ,PVDF coating, all kinds of high simulation wood grain processing , etc. |

| Deep Processing | Cutting , punching . |

| Manufacture Technological Process | Aluminum ingot → Melting and casting → Homogenizing → Extrusion → Aging → Powder coating → Pouring rubber for heat insulation → Acceptance test → Packing → Warehouse → Delivery |

| Certification | ISO 9000 ; ISO 9001 ; ISO 14000 ; CQC ; RoHS |

| Markets | Australia , Germany , North America , Africa and European countries and Southeast Asian area |

Advantages of the extrusion process

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short delivery

(9) Wide range of finishes

(10) Plenty of patterns and colors for your choice.

(11) Strict control for surface finish, very little scratch.

(12) Accurate mold as well as accurate size.

(13) Standard alloy composition

(14) Both ends of the profiles are very plain and with no burr.

Mechanical Properties of Sections under Room Temperature

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

| Aluminum profile surface treatment |

| Class | Min-av erg film thickness | Min-part film thickness |

| AA10 | 10 | 8 |

| AA15 | 15 | 12 |

| AA20 | 20 | 16 |

| AA25 | 25 | 20 |

FAQ ♦

| Q: What is aluminum extrusion, fabrication, and anodize? |

| A: Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die. Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference. |

| A: Aluminum Fabrication refers to building aluminum components by cutting, drilling, slotting, tapping,bending, CNC machining, mechanical assembly and welding. |

| A: Aluminum Anodize is an elector-chemical process of coating aluminum with a thin layer of oxide to increase corrosion resistance and harden the surface. |

| A: Aluminum also can be dyed with various anodizing colors, which in most widely used is Brone shades.

|

About us :

Foshan Kaiya Aluminum Co., Ltd is a comprehensive and professional enterprise integrating research, design production and sales of aluminium extrusion profiles for construction and industrial applications. There are currently 24 aluminum extrusion process lines at 500MT TO 2500MT, 5 process lines for anodizing, 3 process lines for powder coating, 2 process line for painting, 2process line of polishing and brushing. We still have 2 packing line. Our annual production capacity has reached 80,000 tons which is at the forefront of the aluminium industry in China.

Reviews

There are no reviews yet.