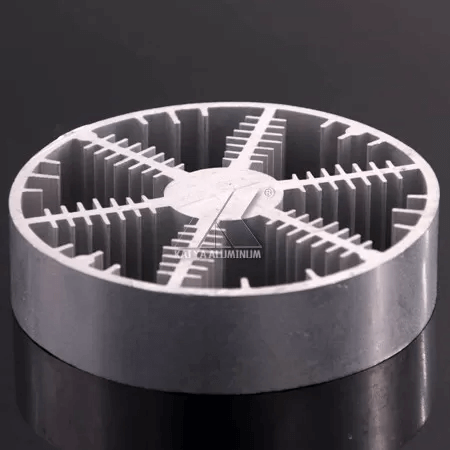

| GRADE: | 6000 Series | TEMPER: | T3 – T8 |

|---|---|---|---|

| COLOR: | Silver | LENGTH: | 2.5-3.5m, Customize |

| PRODUCT NAME: | China Extrusion Profile | SIZE: | According Drawing,customize |

| SURFACE TREATMENT: | Anodize Matt | ALLOY OR NOT: | Is Alloy |

| HIGH LIGHT: | metal curtain rods, extruded aluminum profiles | ||

Matt Anodize Silver 6000 Series Aluminum Alloy Extrusion Curtain Rod

Product Description

| Material | 6063-T5 |

| Temper | T3 – T8 |

| Thickness | General profiles thickness:0.8 – 5.0 mm; Anodized protection thickness: 8 – 25 μm; Powder coating color thickness: 40 – 120 μm |

| Length | 2.5-3.5m, Customized |

| Size | Customized |

| MOQ | 500KG |

| Color | Silver or as your requests |

| Surface Treatment | Mill finish , anodic oxidation , powder coating , elecrophoresis ,PVDF coating, all kinds of high simulation wood grain processing , etc. |

| Deep Processing | Cutting , punching , drilling , tapping , milling , bending , welding etc. |

| Manufacture Technological Process | Aluminum ingot → Melting and casting → Homogenizing → Extrusion → Aging → Powder coating → Pouring rubber for heat insulation → Acceptance test → Packing → Warehouse → Delivery |

| Sample delivery | 2 weeks, one week for mould, the other week for making |

| Markets | Australia , Germany , North America , Africa and European countries and Southeast Asian area |

Advantages of the extrusion process :

The extrusion process provides virtually unlimited opportunities for aluminium product shapes. Costs are cut by designing fewer components, which reduce fabrication and simplify assembly.

These features and benefits are unmatched by other materials and processes:

(1) Quick response

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short lead times

(9) High quality

Mechanical Properties of Sections under Room Temperature

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

Reviews

There are no reviews yet.