| SZIE: | Customize | USAGE: | Shop |

|---|---|---|---|

| FINISH: | Mill Finish | ORIGIN OF PLACE: | Guangdong, China |

| COLOR: | Green | NAME: | Hot Sale Profile |

| TEMPER: | T3-T8 | LENGTH: | Customize |

| HIGH LIGHT: | aluminium furniture profiles, aluminium profile for kitchen cabinets | ||

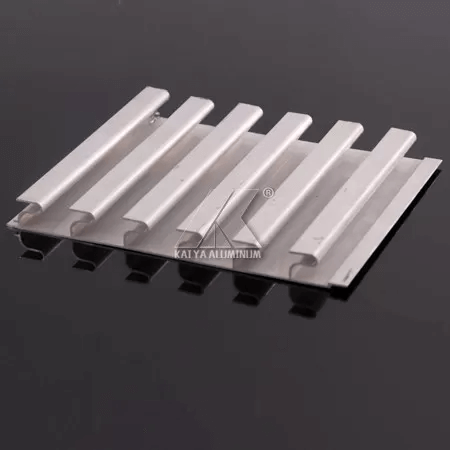

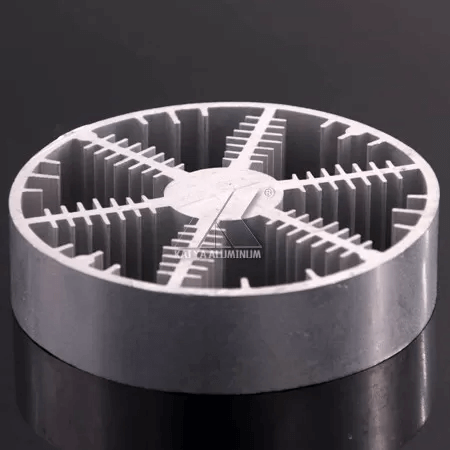

Mill Finish Aluminum Storage Rack in Shop OEM Aluminum Extrusted Profile

Prodictopm Description

| Brand Name | Kaiyamei Aluminum |

| Material | 6063-T5 |

| Temper | T3 – T8 |

| Thickness | General profiles thickness:0.8 – 5.0 mm; |

| Color | Anodized protection thickness: 8 – 10μm Powder coating protection thickness: 40-80μm |

| MOQ | 500KG |

| Diameter | Customize |

| Length | 5.8-6.0m, or as cuostomer request |

| Color | 3D Wood Grain as your requests |

| Finish | Mill finish , anodize, powder coating , elecrophoresis ,PVDF coating, all kinds of high simulation wood grain processing , etc. |

| Deep Processing | Cutting , punching . |

| Certification | ISO 9000 ; ISO 9001 ; ISO 14000 ; CE ; RoHS |

| Markets We Sold | Australia , Germany , North America , Africa and European countries and Southeast Asian area |

| Advantages of the extrusion process | ||

| The extrusion process provides virtually unlimited opportunities for aluminium product shapes. Costs are cut by designing fewer components, which reduce fabrication and simplify assembly. | ||

| These features and benefits are unmatched by other materials and processes | ||

| Complex integral shapes | Cost effective | Low tooling costs |

| Design flexibility | Versatility in joining | Machinable |

| Rapid prototyping | Short lead times | Wide range of finishes |

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

Reviews

There are no reviews yet.