| GRADE: | 6000, 7000 Series | ALLOY OR NOT: | Is Alloy |

|---|---|---|---|

| COVER COLOR: | Milky | SURFACE TREATMENT: | Mill Finish |

| SIZE: | Customized | TEMPER: | T5 |

| HARDNESS: | 2200pa | USAGE: | LED |

| HIGH LIGHT: | led aluminium extrusion profiles,aluminum profile for led | ||

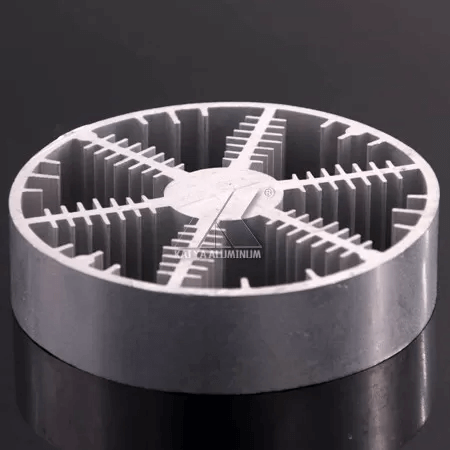

OEM Standard Alloy Aluminum LED Bar With Milky Cover Accessories Profile

1. Brand name: Kaiyamei Aluminum

2. Material: 6063

3. Temper: T3-T8

4. Thickness: General profile 0.8mm – 5.0 mm

5. Color: Bronze, silver, Gold, Black, Champagne or as your request

6. Surface Treatment: Anodize, Powder coating, Wooden grain, elecrophoresis, PVDF coating and so on,

7. Certification: ISO 9000 ; ISO 9001 ; ISO 14000 ; CQC ; RoHS

8. Shape: Square , flat , round , hollow , oval , triangle , U – profiles , L – profiles , T – profiles, H – profiles , customized avaliable

9. Deep Processing: Cutting , punching , drilling , tapping , milling , bending , welding etc.

10. Manufacture Technological Process: Aluminum ingot → Melting and casting → Homogenizing → Extrusion → Aging → Powder coating → Pouring rubber for heat insulation → Acceptance test → Packing → Warehouse → Delivery

11. Markets: Australia , Germany , North America , Africa and European countries and area

Advantages of the extrusion process :

The extrusion process provides virtually unlimited opportunities for aluminium product shapes. Costs are cut by designing fewer components, which reduce fabrication and simplify assembly.

These features and benefits are unmatched by other materials and processes:

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short lead times

(9) Wide range of finishes

General Chemical Composition of Alloy

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

Aluminum profile surface treatment

| Class | Min-av erg film thickness | Min-part film thickness |

| AA10 | 10 | 8 |

| AA15 | 15 | 12 |

| AA20 | 20 | 16 |

| AA25 | 25 | 20 |

Reviews

There are no reviews yet.