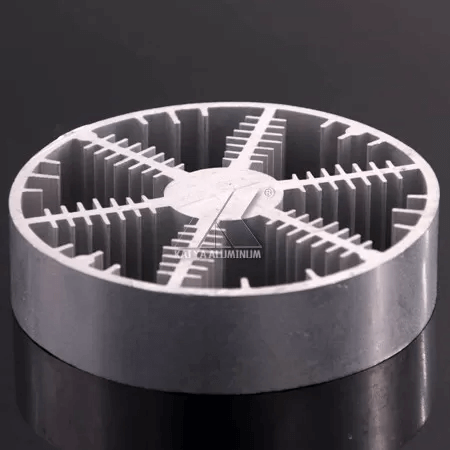

| TEMPLE: | T3-T8 | ALLOY OR NOT: | Is Alloy |

|---|---|---|---|

| COVER COLOR: | Milky | FINISH: | Anodized Matt |

| SIZE: | Customized | ORIGIN OF PLACE: | Guangdong, China |

| CERTIFICATE: | ISO, SGS, RoSH, CQC | USAGE: | LED Profile |

| HIGH LIGHT: | led aluminium extrusion profiles, aluminum profile for led | ||

OEM Aluminum Flexibly Install LED Light With Milky Cover Can Heat Dissipation

Product Description

| Brand Name | Kaiyamei Aluminum |

| Material | 6063-T5 |

| Temper | T3 – T8 |

| Thickness | General profiles thickness:0.8 – 5.0 mm; |

| Color Thickness | Anodized protection thickness: 8 – 10μm Powder coating protection thickness: 40-80μm |

| Diameter | Customize |

| Length | 5.8-6.0m, or as cuostomer request |

| Color | As your requests |

| Surface Treatment | Mill finish , anodize, powder coating , elecrophoresis ,PVDF coating, all kinds of high simulation wood grain processing , etc. |

| Deep Processing | Cutting , punching . |

| Manufacture Technological Process | Aluminum ingot → Melting and casting → Homogenizing → Extrusion → Aging → Powder coating → Pouring rubber for heat insulation → Acceptance test → Packing → Warehouse → Delivery |

| Certification | ISO 9000 ; ISO 9001 ; ISO 14000 ; CQC ; RoHS |

| Markets We Sold | Australia , Germany , North America , Africa and European countries and Southeast Asian area |

Aluminum profile surface treatment

| Class | Min-av erg film thickness | Min-part film thickness |

| AA10 | 10 | 8 |

| AA15 | 15 | 12 |

| AA20 | 20 | 16 |

| AA25 | 25 | 20 |

Anodized surface treatment

| Anodized surface treatment: minimum partial thickness of coating on decorative surface around 8μm – 10μm. |

Powder coating surface treatment

| Powder coating surface treatment: minimum partial thickness of coating on decorative surface≥40μm;Maximum partial thickness≤120μm. |

FAQ ♦

| Q1: What is aluminum extrusion, fabrication, and anodization?

| A: Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die. Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference. Aluminum Fabrication refers to building aluminum components by cutting, drilling, slotting, tapping,bending, CNC machining, mechanical assembly and welding. Aluminum Anodization is an electro-chemical process of coating aluminum with a thin layer of oxide to increase corrosion resistance and harden the surface. Aluminum also can be dyed with various anodizing colors,which in most widely used is Brone shades |

| Q2: What’s the thickness for anodizing? Can you do 15um? | A: Our normal thickness is about 10 um. Yes, we can do 15um and above. |

| Q3: What color you can do for powder coating? The thickness for powder coat? | A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

|

| Q4: What color you can do for wood grain?

| A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide. |

| Q5: What’s the delivery time for samples and mass production? | A: (1). 2-3 weeks to open the new molds and make samples. (2). 3-4 weeks after receipt of deposit and confirmation of the order. |

Reviews

There are no reviews yet.