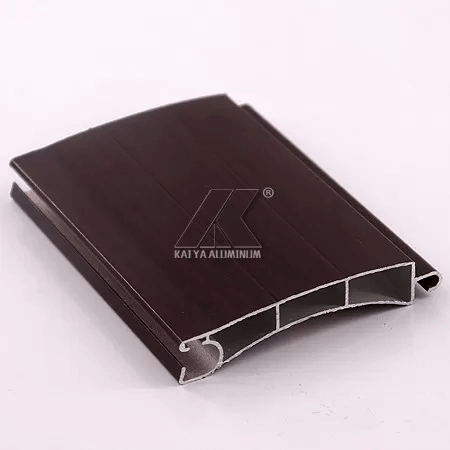

| ORIGIN OF PLACE: | Guangdong, China | GRADE: | 6000. 7000 |

|---|---|---|---|

| FINISH: | Anodized | ALLOY OR NOT: | Is Alloy |

| SIZE: | Customized | COLOR: | Deep Bronze |

| KEYWORD: | Roller Shutter | ||

| HIGH LIGHT: | roller shutter aluminium, aluminium roller shutters | ||

| Advantages of the extrusion process | ||

| The extrusion process provides virtually unlimited opportunities for aluminium product shapes. Costs are cut by designing fewer components, which reduce fabrication and simplify assembly. | ||

| These features and benefits are unmatched by other materials and processes | ||

| Complex integral shapes | Cost effective | Low tooling costs |

| Design flexibility | Versatility in joining | Machinable |

| Rapid prototyping | Short lead times | Wide range of finishes |

Anodized surface treatment

| Anodized surface treatment: minimum partial thickness of coating on decorative surface around 8μm – 10μm. |

Powder coating surface treatment

| Powder coating surface treatment: minimum partial thickness of coating on decorative surface≥40μm;Maximum partial thickness≤120μm. |

Electrophoretic coating surface treatment

| Class | Film thickness um | ||

| Local thickness of anodize oxide film um | paint film local film thickness um | complex film local film thickness um | |

| A | ≥9 | ≥912 | ≥21 |

| B | ≥9 | ≥7 | ≥16 |

| Note: Electrophoretic paint profiles are supplied at B level, and other grades can be supplied as required by customers. | |||

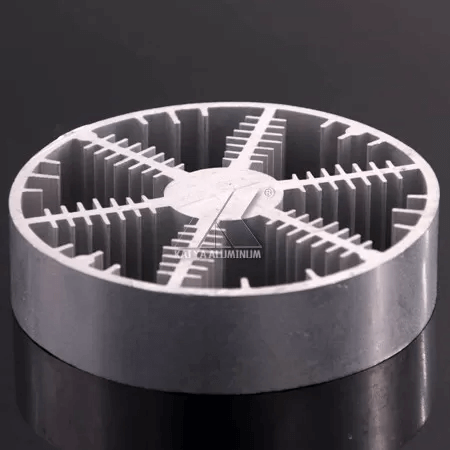

1. Brand name: Kaiyamei Aluminum

2. Material: 6063

3. Temper: T3-T8

4. Thickness: General profile 0.8mm – 5.0 mm

5. Color: Bronze, silver, Gold, Black, Champagne or as your request

6. Surface Treatment: Anodize, Powder coating, Wooden grain, elecrophoresis, PVDF coating and so on,

7. Certification: ISO 9000 ; ISO 9001 ; ISO 14000 ; CQC ; RoHS

8. Shape: Square , flat , round , hollow , oval , triangle , U – profiles , L – profiles , T – profiles, H – profiles , customized avaliable9. Deep Processing: Cutting , punching , drilling , tapping , milling , bending , welding etc.10. Manufacture Technological Process: Aluminum ingot → Melting and casting → Homogenizing → Extrusion → Aging → Powder coating → Pouring rubber for heat insulation → Acceptance test → Packing → Warehouse → Delivery

11. Markets: Australia , Germany , North America , Africa and European countries and area

Reviews

There are no reviews yet.