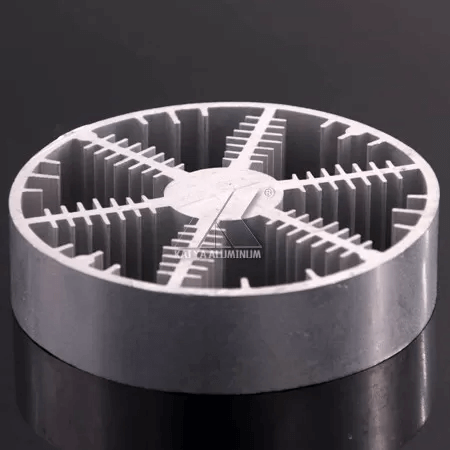

| ORIGIN OF PLACE: | Guangdong,China | USAGE: | Tile |

|---|---|---|---|

| HARDNESS: | 2200pa | FINISH: | Anodized |

| COLOR: | Champagne | OEM: | Yes |

| CERTIFICATE: | ISO9000, ISO9001,ISO14000,CQC,RoHS | SIZE: | Customize Size |

| HIGH LIGHT: | large diameter aluminum extrusions, extruded aluminium profiles | ||

Champagne Anodized OEM Large Size For Tile Eage Side Aluminum Profile With Threads

Prodictopm Description

| Packing : Protect film for each profile, shrink film/Kraft paper exterior for each bundle or pack as customer request. |

| FOB port: Foshan, Shenzhen, Guangzhou |

| Delivery time: 15-20 days after receiving the deposite. |

| Payment term: 30% deposite and 70% balance after the delivery |

| Brand name: Kaiyamei Aluminum |

| Material: 6063 Alloy |

| Temper: T5 |

| Finish: Mill Finished, Anodize, Electrophoresis, Powder Coating ,Polish, Wood grain, Sand Blasting |

| Color: Clear Satin, Bronze, Black, Golden, Silver, Steel Gray…… |

| Thickness: Customize |

| MOQ: 500KG. Usually 12 tons for a 20 feet container; 24 tons for a 40 feet container. |

| Length: 5.8-5.98m, or as customer’s request |

| Sample delivery: Two weeks (one week for mould +one week making sample) |

| Sample design: It is better we can get your drawing or sample, we mainly make according to your design, and we can keep confidential for your design. |

| Maximum extruder machine: 8000 tons; Minimum extruder machine: 500 ton |

| Delivery: About a month, it depends on quantity and size. |

| If the profiles are customized, we will make the sample first, after we get the confirmation from you, we will start production. |

General Chemical Composition of Alloy

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

| Advantages of the extrusion process | ||

| The extrusion process provides virtually unlimited opportunities for aluminium product shapes. Costs are cut by designing fewer components, which reduce fabrication and simplify assembly. | ||

| These features and benefits are unmatched by other materials and processes | ||

| Complex integral shapes | Cost effective | Low tooling costs |

| Design flexibility | Versatility in joining | Machinable |

| Rapid prototyping | Short lead times | Wide range of finishes |

Reviews

There are no reviews yet.