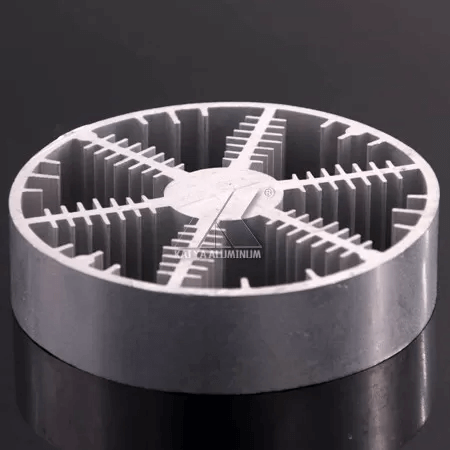

| GRADE: | 6000, 7000 Series | ORIGIN OF PLACE: | Guangdong, China |

|---|---|---|---|

| COVER COLOR: | Milky | SURFACE TREATMENT: | Mill Finish |

| LENGTH: | Customized | TEMPER: | T5 |

| ALLOY OR NOT: | Is Alloy | USAGE: | LED |

| HIGH LIGHT: | led aluminium extrusion profiles, aluminum profile for led | ||

Punching Customize Length Alloy Aluminum LED Bar With Milky Cover Profile

Product Description

| Package:Protect film for each profile, shrink film/Kraft paper exterior for each bundle or pack as customer request. |

| FOB port: Foshan, Shenzhen, Guangzhou |

| Delivery time: 15-20 days after receiving the deposite. |

| Payment term: 30% deposite and 70% balance after the delivery |

| Plenty of patterns and colors for your choice. |

| Strict control for surface finish, very little scratch. |

| Accurate mold as well as accurate size. |

| Standard alloy composition |

Advantages of the extrusion process :

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short delivery

(9) Wide range of finishes

(10) Plenty of patterns and colors for your choice.

(11) Strict control for surface finish, very little scratch.

(12) Accurate mold as well as accurate size.

(13) Standard alloy composition

(14) Both ends of the profiles are very plain and with no burr.

Aluminum profile surface treatment

| Class | Min-av erg film thickness | Min-part film thickness |

| AA10 | 10 | 8 |

| AA15 | 15 | 12 |

| AA20 | 20 | 16 |

| AA25 | 25 | 20 |

Anodized surface treatment

| Anodized surface treatment: minimum partial thickness of coating on decorative surface around 8μm – 10μm. |

Powder coating surface treatment

| Powder coating surface treatment: minimum partial thickness of coating on decorative surface≥40μm;Maximum partial thickness≤120μm. |

Reviews

There are no reviews yet.