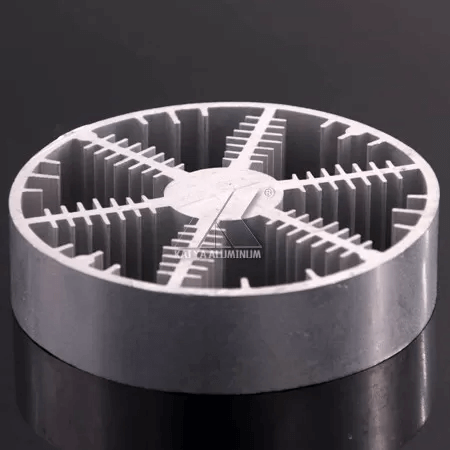

| MATERIAL: | 6063 | FINISH: | Wood Grain |

|---|---|---|---|

| HARDNESS: | T5 | TYPE: | Manufacture Profile |

| USAGE: | Doors | OEM: | Yes |

| ALLOY OR NOT: | Is Alloy | CERTIFICATE: | ISO9000, ISO9001,ISO14000,CQC,RoHS |

| HIGH LIGHT: | aluminium door frame profile, aluminum extrusion profiles | ||

Wood Grain Heat Insulation Broke bridge Door OEM Style Aluminum Extrusted Profile

Prodictopm Description

Packing : Protect film for each profile, shrink film / kraft paper exterior for each bundle or pack as customer request.

FOB port: Foshan, Shenzhen, Guangzhou

Delivery time: 15-20 days after receiving the deposite.

Payment term: 30% deposite and 70% balance after the delivery

Advantages of the extrusion process :

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short lead times

(9) Wide range of finishes

(10) Quick response

(11) Great service

(12) High qualtiy

Powder coating surface treatment

| Powder coating surface treatment: minimum partial thickness of coating on decorative surface≥40μm;Maximum partial thickness≤120μm. |

Anodized surface treatment

| Anodized surface treatment: minimum partial thickness of coating on decorative surface around 8μm – 10μm. |

General Chemical Composition of Alloy

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

Reviews

There are no reviews yet.