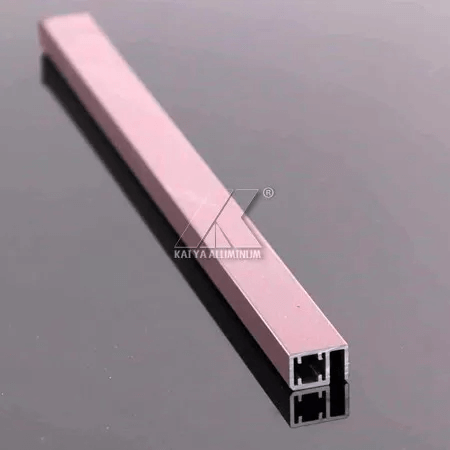

| FINISH: | Anodized | CERTIFICATE: | ISO9000, ISO9001,ISO14000,CQC,RoHS |

|---|---|---|---|

| TEMPER: | T3-T8 | GRADE: | 6000,7000 Series |

| OEM: | Yes | USAGE: | Suitcase |

| ALLOY OR NOT: | Is Alloy | COLOR: | Rose Gold |

| HIGH LIGHT: | aluminium edge trim profiles, decorative metal trim molding | ||

Rose Gold Color Bright Or Brushed Suitcase Accessories Aluminum Extrusted Profile

Package : Protect film for each profile, shrink film / kraft paper exterior for each bundle or pack as customer request.

FOB port: Foshan, Shenzhen, Guangzhou

Delivery time: 15-25 days after receiving the deposite. It depends on goods quantity and size.

Payment term: 30% deposite and 70% balance after the delivery

Material: 6063 Alloy

Temper: T5

Finish: Mill Finished, Anodizing, Electrophoresis, Powder Coating ,Polish, Wood grain, Sand Blasting

Color: Clear Satin, Bronze, Black, Golden, Silver, or as customer’s request

Thickness: 0.8mm – 1.5mm,or as customer’s request

MOQ: 500KG. Usually 12 tons for a 20 feet container; 24 tons for a 40 feet container.

Length: 5.8-5.98m, or as customer’s request

Sample delivery: Two weeks (one week for mould +one week making sample)

Maximum extruder machine: 8000 tons; Minimum extruder machine: 500 ton

Certificate: ISO9000, ISO9001,ISO14000,CQC,RoHS

Aluminum profile surface treatment

| Class | Min-av erg film thickness | Min-part film thickness |

| AA10 | 10 | 8 |

| AA15 | 15 | 12 |

| AA20 | 20 | 16 |

| AA25 | 25 | 20 |

General Chemical Composition of Alloy

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

Mechanical Properties of Sections under Room Temperature

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

Reviews

There are no reviews yet.