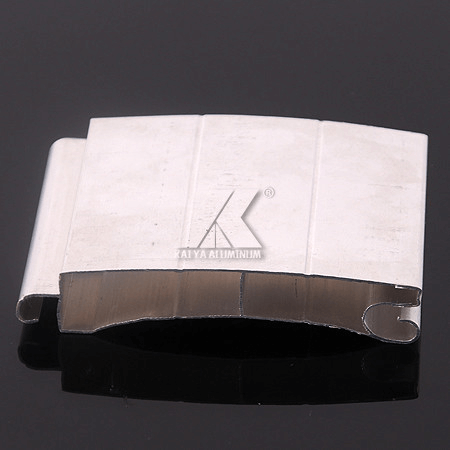

| OEM: | Yes | SIZE: | Customized |

|---|---|---|---|

| SURFACE TREATMENT: | Mill Finish | TYPE: | Manufacture Profile |

| ORIGIN OF PLACE: | Guangdong, China | FINISH: | Silver |

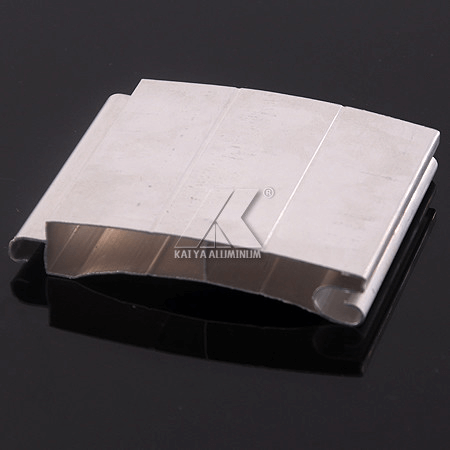

| TEMPER: | T3-T8 | KEYWORD: | Roller Shutter |

| HIGH LIGHT: | rolling shutter material, roller shutter aluminium | ||

Packing : Protect film for each profile, shrink film / kraft paper exterior for each bundle or pack as customer request.

FOB port: Foshan, Shenzhen, Guangzhou

Delivery time: 15-20 days after receiving the deposite.

Payment term: 30% deposite and 70% balance after the delivery

Material: 6063 Alloy

Temper: T5

Brand name: Kaiyamei Aluminum

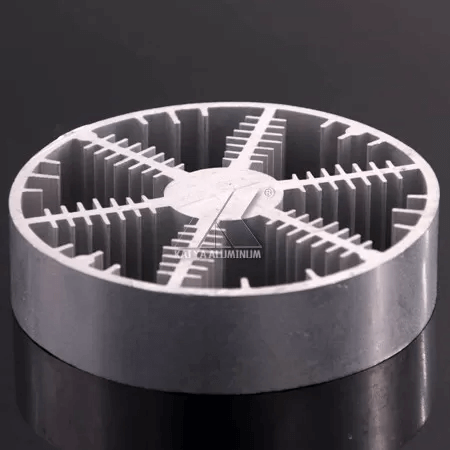

Finish: Mill Finished, Anodizing, Electrophoresis, Powder Coating ,Polish, Wood grain, Sand Blasting

Color: Clear Satin, Bronze, Black, Golden, Silver,

Thickness: 0.8mm – 1.5mm, or as customer’s request

MOQ: 500KG.

Size: Customized, or use our factory drawing

Length: 5.8-5.98m, or as customer’s request

Sample delivery: Two weeks (one week for mould +one week making sample)

Sample design: It is better we can get your drawing or sample, we mainly make according to your design, and we can keep confidential for your design.

Maximum extruder machine: 8000 tons; Minimum extruder machine: 500 ton

Anodized surface treatment

| Anodized surface treatment: minimum partial thickness of coating on decorative surface around 8μm – 10μm. |

Powder coating surface treatment

| Powder coating surface treatment: minimum partial thickness of coating on decorative surface≥40μm;Maximum partial thickness≤120μm. |

Electrophoretic coating surface treatment

| Class | Film thickness um | ||

| Local thickness of anodize oxide film um | paint film local film thickness um | complex film local film thickness um | |

| A | ≥9 | ≥912 | ≥21 |

| B | ≥9 | ≥7 | ≥16 |

| Note: Electrophoretic paint profiles are supplied at B level, and other grades can be supplied as required by customers. | |||

Answer & Questions ♦

Q1: What is aluminum extrusion?

A: Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die. Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference.

Q2: What’s the thickness for anodizing?

A: Our normal thickness is about 10 um.

Q3: What color you can do for powder coating?

A: We can do any color for powder coat as long as you can provide the color sample. O

Q4: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q5: What’s the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Reviews

There are no reviews yet.