| GRADE: | 6063 | OEM: | Yes |

|---|---|---|---|

| COVER COLOR: | Milky | FINISH: | Mill Finish |

| ORIGIN OF PLACE: | Guangdong, China | CERTIFICATE: | ISO, SGS, RoSH, CQC |

| ALLOY OR NOT: | Is Alloy | TYPE: | LED |

| HIGH LIGHT: | led aluminium extrusion profiles, led light aluminium profile | ||

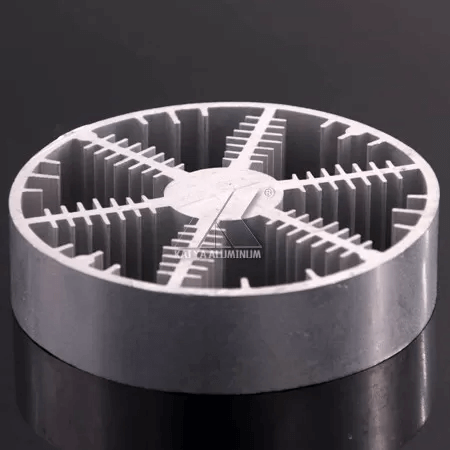

Customize Length OEM ISO Standard Alloy Aluminum LED Bar With CapsProfile

Product Description

| Packing : Protect film for each profile, shrink film/Kraft paper exterior for each bundle or pack as customer request. |

| FOB port: Foshan, Shenzhen, Guangzhou |

| Delivery time: 15-20 days after receiving the deposite. |

| Payment term: 30% deposite and 70% balance after the delivery |

| Brand name: Kaiyamei Aluminum |

| Material: 6063 Alloy |

| Temper: T5 |

| Finish: Mill Finished, Anodize, Electrophoresis, Powder Coating ,Polish, Wood grain, Sand Blasting |

| Color: Clear Satin, Bronze, Black, Golden, Silver, Steel Gray…… |

| Thickness: Customize |

| MOQ: 500KG. Usually 12 tons for a 20 feet container; 24 tons for a 40 feet container. |

| Length: 5.8-5.98m, or as customer’s request |

| Sample delivery: Two weeks (one week for mould +one week making sample) |

| Sample design: It is better we can get your drawing or sample, we mainly make according to your design, and we can keep confidential for your design.

|

| Maximum extruder machine: 8000 tons; Minimum extruder machine: 500 ton |

| Delivery: About a month, it depends on quantity and size. |

| If the profiles are customized, we will make the sample first, after we get the confirmation from you, we will start production.

|

Mechanical Properties of Sections under Room Temperature

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

Advantages of the extrusion process :

The extrusion process provides virtually unlimited opportunities for aluminium product shapes. Costs are cut by designing fewer components, which reduce fabrication and simplify assembly.

These features and benefits are unmatched by other materials and processes:

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short lead times

(9) Wide range of finishes

Reviews

There are no reviews yet.