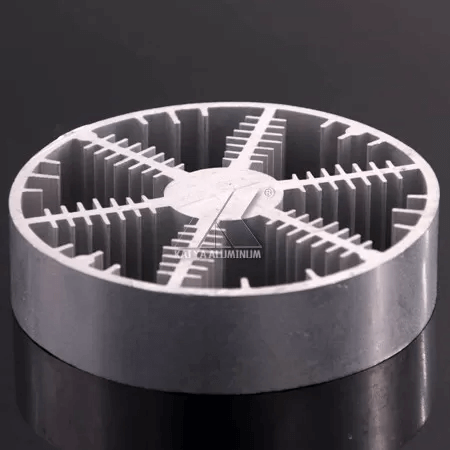

| GRADE: | 6000, 7000 Series | NAME: | Manufacturer Profile |

|---|---|---|---|

| SHAPE: | Hexagon | FINISH: | Mill Finish |

| COLOR: | Natural | BRAND NAME: | KAIYAMEI |

| OEM: | Yes | LENGTH: | Customize |

| HIGH LIGHT: | aluminum heatsink extrusion profiles, extruded heat sink | ||

Hexagon Shape Aluminum Alloy Heat Sink Deep CNC Aluminum Extrusion Profile

| Brand Name | Kaiyamei Aluminum |

| Material | 6063-T5 |

| Temper | T3 – T8 |

| Thickness | General profiles thickness:0.8 – 5.0 mm; |

| Color Thickness | Anodized protection thickness: 8 – 10μm Powder coating protection thickness: 40-80μm |

| Diameter | Customize |

| Length | 5.8-6.0m, or as cuostomer request |

| Color | 3D Wood Grain as your requests |

| Surface Treatment | Mill finish , anodize, powder coating , elecrophoresis ,PVDF coating, all kinds of high simulation wood grain processing , etc. |

| Deep Processing | Cutting , punching . |

| Certification | ISO 9000 ; ISO 9001 ; ISO 14000 ; CQC ; RoHS |

| Markets | Australia , Germany , North America , Africa and European countries and Southeast Asian area |

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Great Service

(6) Machinable

(7) Rapid prototyping

(8) Short Delivery times

(9) High Quality

Questions & Answer

| Q: What’s the thickness for anodizing? Can you do 15um? A: Our normal thickness is about 10 um. Yes, we can do 15um and above. |

| Q: What color you can do for powder coating? The thickness for powder coat? A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um. |

| Q: What color you can do for wood grain? A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide. |

| Q: What’s the delivery time for samples and mass production? A: (1). 2-3 weeks to open the new mold and make samples. (2). 3-4 weeks after receipt of deposit and confirmation of the order.

|

Genearl Profile

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

Mechanical Properties of Sections under Room Temperature

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

Reviews

There are no reviews yet.