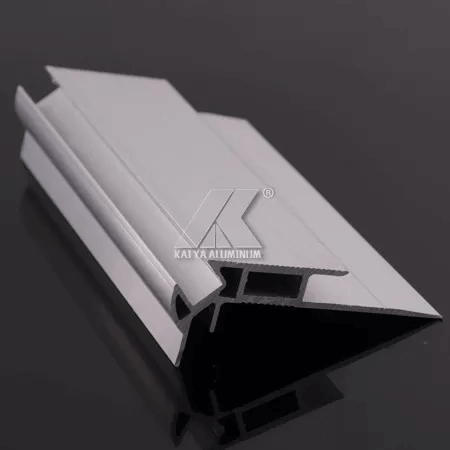

| STYLE: | Thailand’s Profile | USAGE: | Windows |

|---|---|---|---|

| FINISH: | Powder Coating | ORIGIN OF PLACE: | Guangdong, China |

| TYPE: | OEM | COLOR: | White |

| TEMPER: | T3-T8 | OEM: | Yes |

| HIGH LIGHT: | aluminum profile for furniture, aluminium furniture profiles | ||

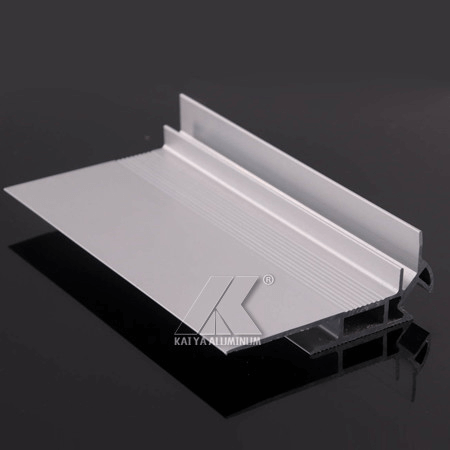

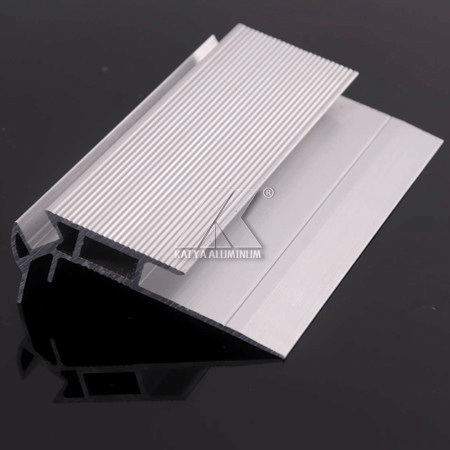

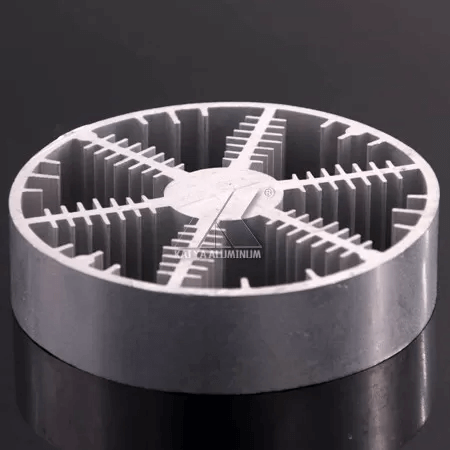

High Grade Mill Finish Aluminum Ladder in Stage OEM Aluminum Extrusted Profile

Prodictopm Description

1) Material: 6061,6063

2) Name: Aluminum Ladder

3) Brand Name: KAIYAMEI ALUMINUM

4) Finish: Mill Finish, Anodize, Electrophoresis, Powder Coating ,Polish, Wooden grain, Sand Blasting

5) Color: Clear Satin, Bronze, Black, Golden, Silver, other colors for Powder Coating

6) MOQ: 500KG. Usually 12 tons for a 20 feet container; 24 tons for a 40 feet container.

7) Length: 5.8-5.98m, or as customer’s request

8) Sample delivery: Two weeks (one week for mould +one week making sample)

9) Sample design: It is better we can get your drawing or sample, we mainly make according to your design, and we can keep confidential for your design.

10) Maximum extruder machine: 8000 tons; Minimum extruder machine: 500 ton

11) Delivery: About a month

Advantages:

1. Plenty of patterns and colors for your choice.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

6. Complex integral shapes

7. Cost effective

8. Low tooling costs

9. Design flexibility

10.Versatility in joining

11. Machinable

12. Rapid prototyping

13. Short lead times

14. Wide range of finishes

15. High qualtity

16. Quick response

17. Professional team

| Alloy | 6063(%) | 6061(%) | 6082(%) |

| Silicon Si | 0.20~0.60 | 0.40~0.80 | 0.7~1.2 |

| Iron Fe | 0.35 | 0.70 | 0.5 |

| Copper Cu | 0.10 | 0.15~0.40 | 0.1 |

| Manganese Mn | 0.10 | 0.15 | 0.4~0.8 |

| Manganese Mg | 0.45~0.90 | 0.18~1.2 | 0.6~0.8 |

| Chromium Cr | 0.10 | 0.04~0.35 | 0.25 |

| Zine Zn | 0.10 | 0.25 | 0.2 |

| Titanium Ti | 0.10 | 0.15 | 0.1 |

| Others(each) | 0.05 | 0.05 | 0.05 |

| Others | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

| Alloy | State | Tensile strength test | Hardness test | ||||||||

| Tensile strength Rm M pa | Non-proportional Stretching Stress | Stretching rate | Pattern thickness | HV | HW | ||||||

| Rp0.2Mpa | (A50mm%) | mm | HV | HW | |||||||

| 6063 | T4 | 130 | 75 | 14 | – | ||||||

| T5 | 160 | 110 | 8 | 0.8 | 58 | 8 | |||||

| T6 | 205 | 180 | 8 | – | |||||||

| 6061 | T4 | 184 | 110 | 16 | – | ||||||

| T6 | 265 | 245 | 8 | – | |||||||

| 6082 (6351) | T4 | 205 | 110 | 12 | – | ||||||

| T6 | 290 | 250 | 6 | – | |||||||

Reviews

There are no reviews yet.